servicios y productos

Extinguishing Systems

Water Based Extinguishing Systems

For the purposes of fire protection, it is a system made up of underground and overhead pipes, designed in accordance with engineering standards for fire protection. The installation includes one or more sources of automatic water supply. The part of the sprinkler system that is located on the ground is a specially dimensioned or hydraulically designed pipe network installed in a building or structure area - generally superior - to which sprinklers are attached following a systematic distribution pattern. The valve that controls each vertical feed pipe in the system is located on the vertical feed stem or its feed pipe. Each vertical stem of the sprinkler system includes a device that triggers an alarm when the system is in operation. The system is usually activated by the heat generated by a fire and discharges water on the burning surface. The systems we operate are wet systems, dry systems, pre-action systems, deluge systems and foam-based systems. All designed based on NFPA 13, 11, 24, 20 and other applicable standards.

Humid

System

System that uses automatic sprinklers, connected to a system of pipes that contain pressurized water and that, in turn, is connected to a water supply; in such a way that it discharges water immediately after a sprinkler is opened by the heat of the fire.

dry

system

System that uses automatic sprinklers, connected to a piping system that contains air or nitrogen under pressure, whose release (from the opening of a sprinkler), allows the water pressure to open a valve that is known as a dry valve and water flows into the system piping and discharges through open sprinklers.

PRE-ACTION

SYSTEM

Sprinkler system that uses automatic sprinklers connected to a piping system that contains air that may or may not be under pressure; with a supplemental detection system installed in the same areas as the sprinklers. Activation of the detection system opens a valve that allows water to flow into the sprinkler system piping and will be discharged after a sprinkler is opened by the heat of the fire. This system is divided into three types:

•Unique interlock system. – Systems that allow the entry of water into the sprinkler piping when the detection devices operate.

•Non-interlocking system. – Systems that allow the entry of water into the sprinkler pipe when the detection devices or automatic sprinklers operate.

•Double interlock system. – Systems that allow water to enter the sprinkler piping when detection devices and automatic sprinklers operate at the same time.

DELUGE

SYSTEM

Sprinkler system that uses open sprinklers, connected to a piping system, connected in turn to a water supply through a valve that is opened by the operation of a detection system installed in them. Sprinkler areas. When this valve opens, water flows into the system piping and discharges from all the sprinklers connected to it.

Foam Based Systems

Foams as an extinguishing agent consist of a mass of air-filled bubbles that form from aqueous solutions of blowing agents of different formulas. Since the foam is lighter than the aqueous solution from which it is formed and lighter than flammable or combustible liquids, it floats on them, producing a continuous layer of aqueous material that displaces the air, cools and prevents the release of steam with the purpose of stopping or preventing combustion; These systems can be managed based on monitors, hydrants, sprinklers, deluge, surface injection systems and sub-surface injection systems; There are different types of foam, among them are the following:

Mechanical foam

Protein foam

Aqueous Film Forming Foam (AFFF)

Alcohol Resistant Aqueous Film Forming Foam (AR-AFFF)

Hidrants and monitors

These discharge devices are used for manual protection in case of fire and must be operated by trained personnel; they are located depending on the different needs of the project. These systems are manually operated, which means that they require personnel to activate them. For the hydrant system, when a Fire occurs at any point in the plant, a person must go to the nearest hydrant, open the hydrant valve, go to the hose to the point of fire and open the nozzle directing the jet to the fire until sofocation. For monitor systems when a fire starts, a person should go to the nearest monitor, open the discharge nozzle and direct the jet to the fire until suffocating. All according to the requirements of NFPA 14, 24.

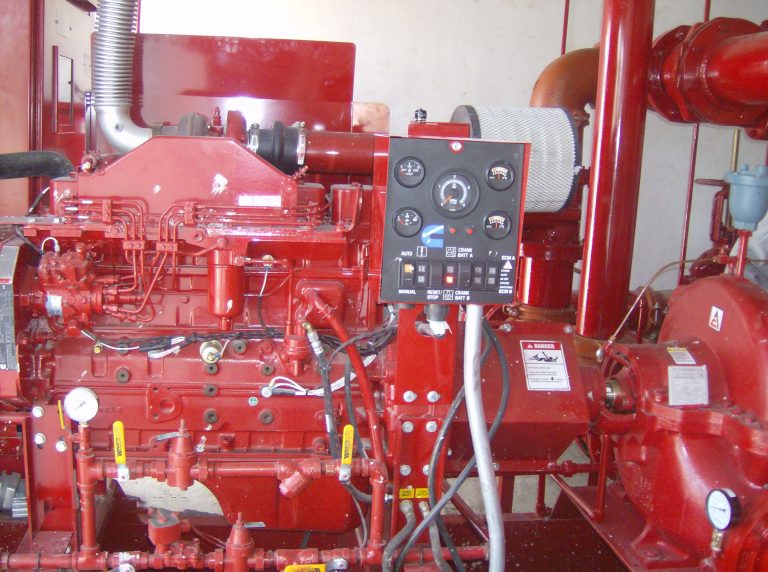

Pumping Equipment

This equipment consists of three pumps:

The pumping equipment will be automatically operated at manual start and stop, all according to the requirements of NFPA 20.

Jockey Pump

It is in charge of constantly keeping the firewater pipe pressurized, is powered by an electric motor, and is automatically operated by means of a control panel. When the pressure in the pipe drops due to a leak or change in pressure, this pump starts operating, restoring the pressure in it.

Service Pump

Automatically starts operating when one or more sprinklers are open and when the jockey pump fails to restore pressure in the system. This pump is powered by an internal combustion or electric motor (as required) and is of sufficient capacity to supply water at the pressure required by codes and / or design criteria.

Backup Pump

If required, this pump has the same characteristics as the service pump, and it automatically starts operating when the pressure continues to drop, because either the water demand is high or the water supply did not start operating. Service pump for lack of electric power or some other setback.

Fire Water Storage Tanks

Every firefighting system must have at least an automatic water supply; This water supply must be reliable and capable of providing the flow and pressure required for the duration of the fire attack, these supplies can be screw-on tanks, weld able tanks or tanks, among others, working in conjunction with a pumping team.

Contact

Address Vía Gustavo Baz #379, Colonia San Agustín, Naucalpan, Edo. de México